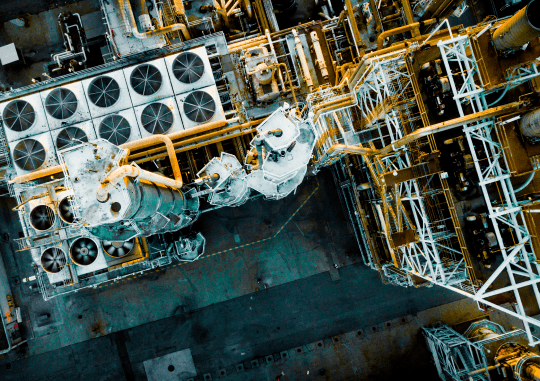

The Petronas Second Refinery (PSR-2) located in Melaka and is operated by Malaysia Refining Company, a subsidiary of Petronas. Commissioned in 1999, it refines indigenous crude oil into high value petroleum products for domestic and export markets.

In 2007, the debottlenecking and revamp project was started to increase the overall Melaka refinery throughput from 130,000 to 175,000 barrels of crude oil per day.

This project included:

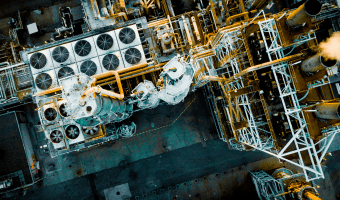

To protect the Melaka PSR-2 Refinery pipelines from freezing and to maintain the required temperatures.

Our company awarded two contracts for supply of electric heating systems to the Melaka PSR-2 Refinery. To protect the pipelines from freezing and to maintain the requested temperatures, self-regulating cables BTC and BTX were chosen.

Please fill out the form below so we can create a custom-made heat tracing solution for your specific project.

The Petronas Second Refinery (PSR-2) located in Melaka and is operated by Malaysia Refining Company, a subsidiary of Petronas. Commissioned in 1999, it refines indigenous crude oil into high value petroleum products for domestic and export markets.

In 2007, the debottlenecking and revamp project was started to increase the overall Melaka refinery throughput from 130,000 to 175,000 barrels of crude oil per day.

This project included:

To protect the Melaka PSR-2 Refinery pipelines from freezing and to maintain the required temperatures.

Our company awarded two contracts for supply of electric heating systems to the Melaka PSR-2 Refinery. To protect the pipelines from freezing and to maintain the requested temperatures, self-regulating cables BTC and BTX were chosen.

What challenge can we help you overcome? Let us create a custom-made solution for your project. Fill out the form below to get in touch.